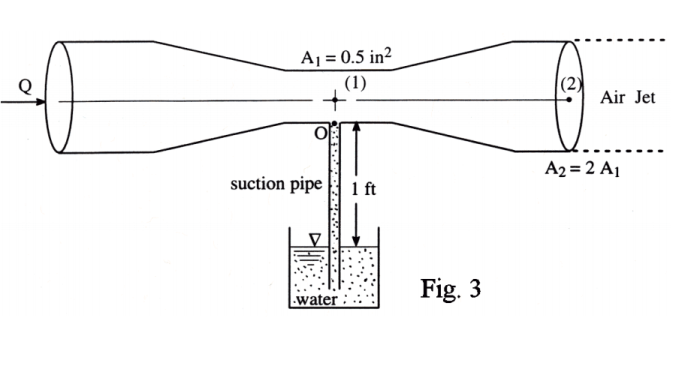

The operation of a double suction riser depends on a combination of pressure differentials and suction head, creating a reliable and efficient means of fluid transfer. Understanding these principles is crucial for optimizing riser performance and ensuring its effective operation in various industrial applications.

The fundamental principle behind a double suction riser’s operation lies in the pressure differentials generated between the suction and discharge sides of the pump. These differentials create a pressure gradient that drives the fluid through the riser. Additionally, the suction head, which is the vertical distance between the fluid level in the reservoir and the pump inlet, plays a significant role in determining the riser’s performance.

1. Understanding the Principles of Double Suction Riser Operation

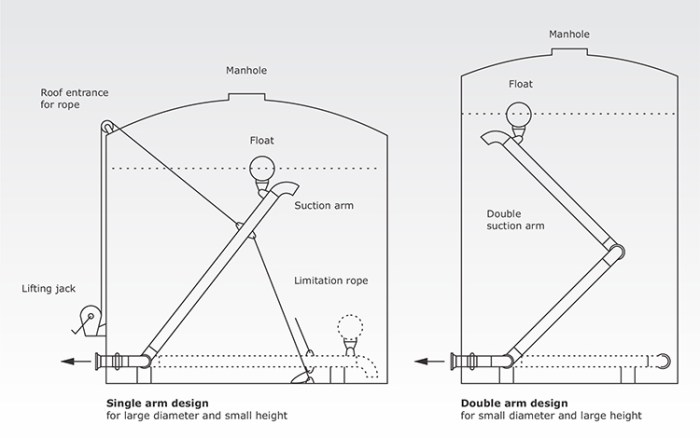

Double suction risers are vertical pipes used to lift fluids from a reservoir to the surface. They are typically used in offshore oil and gas production, but can also be found in other industries such as water treatment and mining.

The operation of a double suction riser is based on the principle of pressure differentials. The pressure at the bottom of the riser is greater than the pressure at the top, which creates a pressure gradient that drives the fluid up the riser.

The suction head is the difference between the pressure at the bottom of the riser and the pressure at the surface. The suction head is a critical factor in determining the performance of a double suction riser. A higher suction head will result in a higher flow rate.

2. Design Considerations for Double Suction Risers

The design of a double suction riser is critical to its performance. The following factors should be considered when designing a double suction riser:

- Diameter: The diameter of the riser should be large enough to allow for the required flow rate.

- Length: The length of the riser should be as short as possible to minimize pressure losses.

- Materials: The riser should be constructed of materials that are resistant to corrosion and erosion.

Proper installation and maintenance are also important for the performance of a double suction riser. The riser should be installed vertically and should be properly anchored to prevent movement.

3. Performance Characteristics of Double Suction Risers

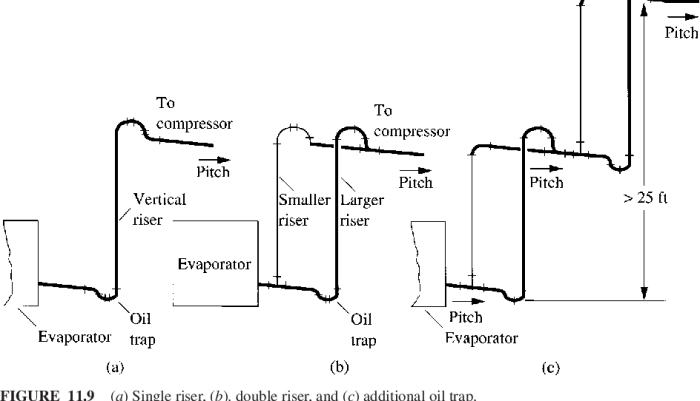

Double suction risers have a number of advantages over other types of risers. These advantages include:

- High flow rates

- Low pressure losses

- High efficiency

The performance of a double suction riser is affected by a number of factors, including the diameter, length, and materials of the riser, as well as the suction head and the fluid properties.

4. Applications of Double Suction Risers

Double suction risers are used in a variety of industries, including:

- Offshore oil and gas production

- Water treatment

- Mining

In offshore oil and gas production, double suction risers are used to lift oil and gas from the reservoir to the surface. In water treatment, double suction risers are used to lift water from a reservoir to a treatment plant.

In mining, double suction risers are used to lift ore from a mine to the surface.

5. Troubleshooting and Maintenance of Double Suction Risers: The Operation Of A Double Suction Riser Depends On

Double suction risers are relatively low-maintenance, but they can experience problems from time to time. Common problems include:

- Clogging

- Corrosion

- Erosion

Clogging can be prevented by installing a filter at the bottom of the riser. Corrosion can be prevented by using corrosion-resistant materials. Erosion can be prevented by using erosion-resistant materials or by installing a sacrificial anode.

Detailed FAQs

What are the key factors that affect the operation of a double suction riser?

The key factors that affect the operation of a double suction riser include pressure differentials, suction head, riser diameter and length, material selection, and proper installation and maintenance.

How does the suction head impact the performance of a double suction riser?

The suction head significantly influences the performance of a double suction riser. A higher suction head leads to increased pressure differentials, resulting in higher flow rates and improved efficiency.

What are the advantages of using double suction risers?

Double suction risers offer several advantages, including higher flow rates, reduced pressure losses, improved efficiency, and the ability to handle larger solids.